After the demagnetization treatment, the workpiece can be completely non-magnetic and not adsorb other ferromagnetic materials. It is easy to clean and reduce the friction damage between the workpiece and the workpiece. Demagnetization treatment can reduce residual stress and increase the life of the workpiece. Demagnetization treatment technology is a new type of non-heat treatment metal material performance treatment technology. It uses alternating magnetic field technology to change the internal magnetic field distribution structure of the part, so as to achieve the purpose of a demagnetizer and improve the overall comprehensive mechanical performance of the workpiece. To

Demagnetization processing technology integrates electronics, ferromagnetism, and metal materials into one, and has a high technological content. The abrasion resistance, durability and fatigue resistance of the magnetically treated workpiece can be significantly improved.

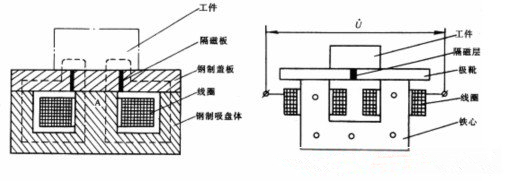

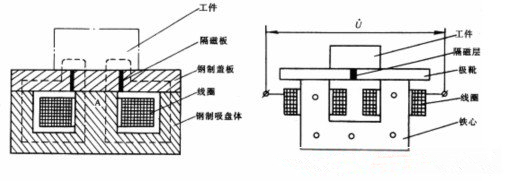

Internal structure

Desktop demagnetizer-mainly composed of four parts: cover, coil, iron core and bottom shell (as shown below)

Product application range and characteristics

1. It is suitable for demagnetization of small and medium-sized molds, small and medium-sized equipment, plates, measuring tools, parts and accessories in small and medium batches.

2. The built-in heat dissipation system and temperature control device ensure the uninterrupted and continuous use of the demagnetizer.

3. The demagnetization working surface is large, the demagnetization power is very strong, and the demagnetization effect is outstanding.

4. The Tesla current generated by material science and magnetism is used to ensure a better demagnetization effect.

5. This series of products are made of high-quality materials, beautiful workmanship, and quality assurance.

6. For materials with strong magnetic retention: such as high carbon steel, nickel-chromium steel, spring steel, die steel, bearing steel, etc., it can also be easily demagnetized;

7. It can be widely used in electronics, communications, small and medium-sized machinery and equipment, ship parts, hardware processing, laboratories in various universities, medical treatment and many other industries.

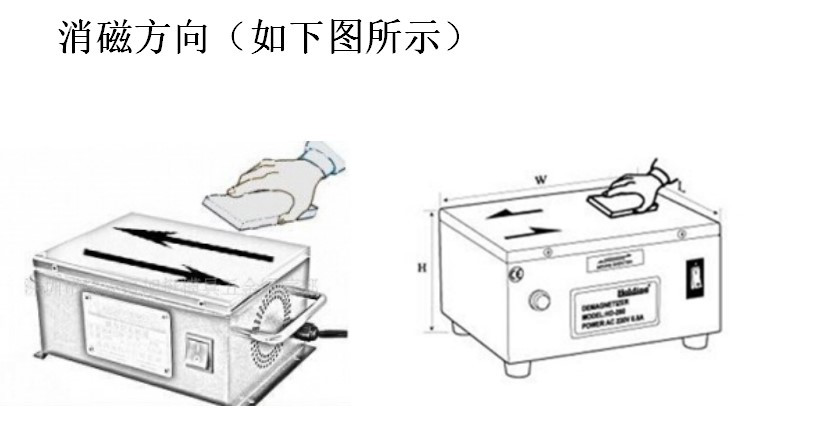

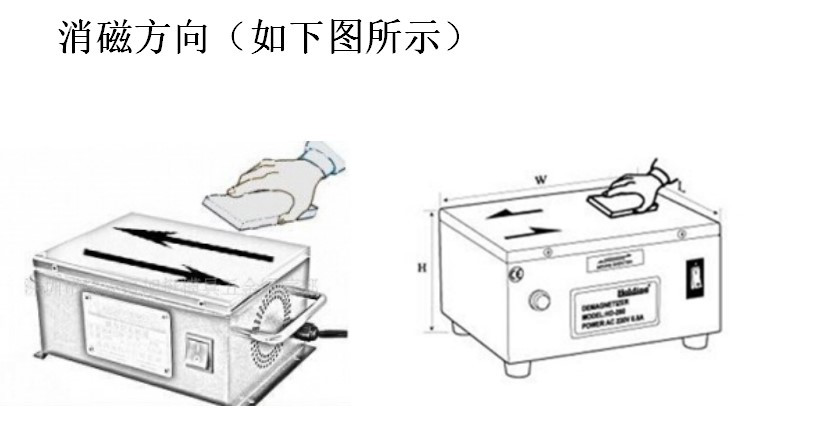

Degaussing direction

1. Insert one end of the power cord into the AC220V electrical socket, the green indicator light will be on, and the cooling system will start to work;

2. Turn on the demagnetization switch (switch button, etc.), the red indicator light is on, and the demagnetizer starts to work;

3. Place the items to be demagnetized on the demagnetization working surface;

4. Move the workpiece away from the demagnetization work area at a uniform speed, and the item will be demagnetized;

5. It is recommended to use sealed or semi-sealed non-magnetic containers to load small parts and components;

6. For long workpieces that exceed the length of the working surface of the demagnetizer, slowly move the workpiece from one end of the working surface of the demagnetizer to the other end of the working surface and move it out of the working surface.